Basic Steps of a Lockout/Tagout Process

Some basic steps are common to all lockout/tagout procedures, though you will need to get more specific for your individual situation. OSHA requires you to have a lockout/tagout process. In a BLR webinar entitled “Lockout/Tagout: How Small Tweaks To Your Program Can Mean Big Savings in Costs and Injuries,” Michael D. Lawrence outlined the basic steps.

Step 1: Identify energy sources and shut off energy to the affected equipment. (Use normal stopping or running procedures for the machine.)

Step 2: Notify others – in particular all affected employees.

Step 3: Shutdown the equipment, using normal stopping procedures for the machine.

Step 4: Isolate the equipment from the energy source.

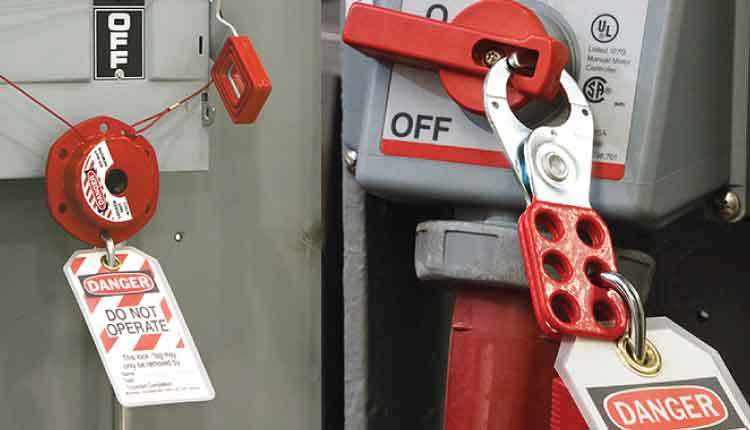

Step 5: Lockout/tagout the equipment by affixing locks and tags to each energy source controlling device.

Step 6: Release any stored energy from capacitor banks, springs, compressed air, steam, hydraulics, etc.

Step 7: Verify isolation of energy has occurred by trying the equipment.

Step 8: Perform servicing.

Step 9: Release the equipment from lockout/tagout.

When restarting the machinery, here are some steps to follow:

– Ensure that nonessential items are removed from equipment.

Ensure that equipment components are intact.

Check the area to ensure that all affected employees are safely positioned or removed from the area.

Notify all affected employees and site supervisor before re-energizing the equipment.

Remove lockout/tagout devices.

Reenergize equipment to ensure safe operation.